The Failure Mode and Effects Analysis(FMEA) is a proactive systematic step-by-step risk assessment process for in-depth evaluation of processes and/or products to identify where and how failures might occur in their design, manufacture, and assembly and the consequences of the failures. This, in turn, helps in identifying areas that need prompt attention.

Failure mode refers to the different ways or modes that a product or process might fail, with failures being the actual errors that occur and have consequences on those using the process or product. Effect analysis, on the other hand, refers to studying the consequences that arise from the different failure modes identified.

FMEA is very useful in test management, the process of managing and monitoring testing activities to ensure resources are focussed on the most important or high-risk areas, thus ensuring high-quality testing of products.

In such cases, FMEA is used to identify potential risks and defects in a testing process and to prioritize them based on their impact on the quality and reliability of the product being tested.

It also helps those conducting the tests to identify failure modes, such as hardware failures or software bugs, and determine their effects on the testing process and the product being tested.

Why FMEA is important

No product or service is ever perfect or completely error-free. However, it doesn’t mean that action should not be taken to minimize errors as much as possible.

Errors are costly, especially when they occur or are discovered in the late development stages of a product or process. The earlier you can detect an error, the better. This is why FMEA is crucial when designing, manufacturing, or assembling products or processes.

FMEA allows for early detection and prioritization of failures according to the severity of their consequences, ease of detection, and how often they occur. Action can then be taken to minimize or completely eliminate failures starting with failures that have more severe consequences.

This, in turn, helps prevent the re-occurrence of failures, and even when a failure mode occurs, users will have a guide on actions to take to handle the failure.

When to perform Failure Mode and Effects Analysis

FMEA is best performed in situations where failures might arise, which generally includes activities that result in changes in design, products, features, or different use of existing products.

Some of the situations where it might be a good idea to perform FMEA include:

- When a new product or process is being designed or redesigning an existing product

- When you want to use an existing product in a different way other than the intended one, or you want to apply an existing process in a new way

- When you want to improve an existing product, process, or service

- When you want to analyze the failures and integrity of a product or service

- When developing control plans for a new process, or a modified existing process

It is also highly recommended that FMEA be performed periodically in the lifetime of a product or process.

Examples of FMEA

FMEA analysis has been adopted by many different industries. In software development, FMEA can be used to identify possible failure modes in a banking application being developed. The failure modes could include security breaches, miscalculations, or even data corruption during transactions.

The effects of these failure modes could be financial loss or loss of sensitive data. By conducting an FMEA analysis, software developers can note the potential failure modes, ascertain their level of severity, and develop action plans to address high-risk failure modes.

In manufacturing, an FMEA analysis can be used to identify failure modes in a process like injection molding. Examples of failure modes that can be identified in such a process could include production delays, mold-breaking, and incorrect material injection.

The effects could result in the making of substandard molds, increased costs, and decreased production efficiency. An FMEA analysis can be used to identify these failure modes and address them to improve the process quality and overall outcome of the process on the manufacturing company.

The FMEA Process

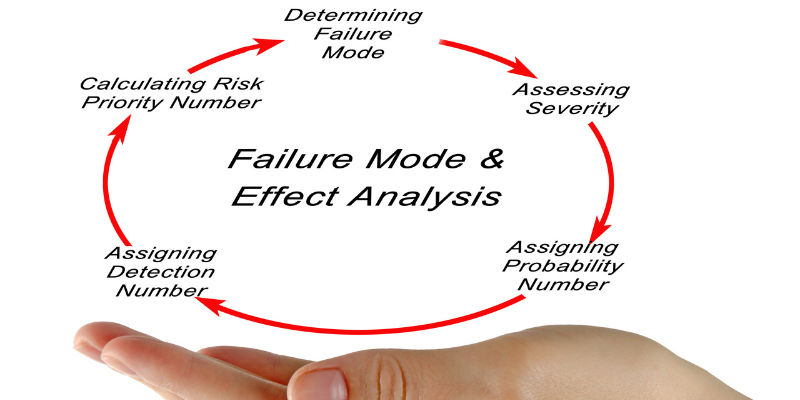

During an FMEA analysis, the following steps are taken to identify and address potential failures in a product or process:

- Define the scope of the FMEA analysis and clearly identify the type of FMEA being conducted, what it will cover, and how detailed it will and make sure all members of the team clearly communicate this to the team conducting the FMEA

- Assemble a team of people with diverse knowledge and experience on the product, process, or service and an understanding of customer needs

- Break down the system or process into manageable components, functions, or steps to analyze.

- For each component or function, identify potential failure modes that could occur.

- Determine the effects of each potential failure mode on the system, products, or process

- Assign a severity, occurrence, and level detectability rating to each potential failure mode based on the potential effects of the failure. The rating scale is typically from 1 to 10, with 10 being the most severe.

- Identify the potential causes of each failure mode. This can be done by brainstorming or using other tools such as the Ishikawa diagram or 5 Whys.

- Rank each failure mode based on the selected criteria. This could be based on how often the failure mode occurs, the ease of detection, or how severe the failure mode is

- Develop and implement action plans to address the most critical failure modes. This can include redesign, process changes, or additional controls

- Document and update the FMEA, noting the identified failure modes and the measure taken to mitigate them. This is then communicated to relevant stakeholders.

An FMEA analysis is a continuous process that organizations should periodically do. Here are some software solutions that will make your FMEA process stress-free and very effective.

ReliaSoft XFMEA

XFMEA by Reliasoft is a robust, feature-rich FMEA software that is used by companies such as Rolls Royce, Coca-cola, and BAE systems.

The software allows users to perform four different kinds of FMEA analysis, namely, Process FMEA, System FMEA, Design FMEA, and Failure modes, effects, and criticality analysis (FMECA). This is in addition to supporting the major industry standards for all types of FMEA analysis.

XFMEA allows for easy configuration of the analysis project to align with any risk assessment methodology that is used in conjunction with FMEA.

Additionally, XFMEA allows the transfer of data from Design FMEA to Process FMEA, automatic generation of tests to be performed during FMEA, offers flexible data management tools, and it supports a process flow diagram that provides a logical, visual depiction of the process that is being analyzed.

Intelex FMEA

Intelex FMEA is FMEA software with excellent support for collaboration and a team-based problem-solving approach, in addition to helping organizations standardize and streamline the FMEA process and workflows.

It allows users to identify and eliminate potential failures that might occur in their products and processes and also easily keep track of all FMEAs across an entire organization. It also allows users to monitor the activities taken to counter the identified risks and build a reusable knowledge base of potential effects and causes.

DataLyzer FMEA

The DataLyzer FMEA software comes as a module in the DataLyzer Software suite. However, it can also be operated as a stand-alone module. Datalyzer FMEA allows for the customization of FMEA criteria and classification symbols to match the industry where the software is being used to conduct FMEA analysis.

It also supports the assignment of users, roles, and permission to guide access to resources and thus can be used with multiple users in different departments without mismanagement of user rights and privileges.

Datalyzer FMEA also allows for easy creation and generation of process flows to guide the FMEA process and also allows for easy maintenance of FMEAs using references FMEAs which are updated automatically in all FMEA using a particular reference FMEA.

It also supports root cause analysis of failures and the generation of detailed reports from performed FMEA and can easily be adopted by organizations as it is relatively easy to learn how to use and also offers free tutorials on how to use it in conducting FMEA analysis.

Relyence FMEA

Relyence FMEA touted as the complete FMEA solution, is packed with features that make the process of FMEA analysis stress-free, as Relyence does all the heavy lifting for users. First, users can perform any type of FMEA analysis from Design FMEAs, Process FMEAs, piece-part FMECAs, and FMEA-MSRs, and users can also run their own custom FMEAs.

To make the process of conducting an FMEA even simpler, users can select from available custom FMEA templates or run their own customized FMEAs. Users also have access to the Relyence knowledge bank, allowing them to reuse, search and sync their FMEA analysis.

Relyence FMEA allows for access to conducted FMEA analysis anytime, anywhere, and on any device, including mobile devices. It also supports role-based permissions and effective access control, and it comes with always-in-sync features which ensure conducted FMEAs are always up to date, and coverage is complete.

Users also get a dashboard that gathers and organizes FMEA data allowing for a holistic overview of conducted FMEAs.

PQ-FMEA+

PQ-FMEA+ is FMEA software available in eight different languages and supports the creation of different FMEA analyses and also provides features for control planning and drawing process flow diagrams. With this FMEA solution, users spend less time preparing for FMEA analysis and experience an overall improvement in teamwork during FMEA analysis.

PQ-FMEA+ also for easy modification of FMEA analysis, easy documentation of FMEA analysis, and ensures strong data integrity in an FMEA analysis.

QT9™ QMS FMEA

QT9™ QMS FMEA management module comes as part of the QT9™ QMS software, and it offers a cross-platform FMEA solution that automates the FMEA process eliminating the need for conducting manual FMEA, which is time-consuming.

The QT9™QMS runs on android, iOS, Windows or any web browser allowing access to the FMEA analysis from any device anywhere in the world.

QT9™ QMS FMEA allows for the fast creation and revision of FMEA records using inbuilt FMEA records. It allows the storage of searchable FMEA records, automatic calculation of risk priority numbers for identified failures, and provides users with email alerts whenever any changes happen in the FMEA analysis.

Users can also see a timeline of all the changes that have happened during an FMEA analysis. Users also have access to an easy-to-use dashboard with a personalized view for different users collaborating in an FMEA analysis.

FMEA Studio

FMEA Studio, developed by iQA System, is a robust FMEA software add-in for Microsoft Excel and only works in the Windows operating system.

FMEA Studio works right inside Microsoft Excel and provides templates for different types of FMEA analysis, such as basic FMEA, Design FMEA, Process FMEA, Software FMEA, and Healthcare FMEA. Users can also create their own customized templates for their own FMEA analysis.

FMEA studio also comes with features for FMEA, such as a process flow diagram, evaluation of risks according to action priority table, evaluation of FMEA risks using 2D and 3D matrixes, and ranking tables for easy ranking of severity, occurrence, or detection level.

Users of FMEA studio also have the benefit of easily editing their FMEA documents and sharing them with other users. Compared to other FMEA solutions, FMEA studio is relatively cheaper.

SoftExpert FMEA

SoftExpert FMEA is an FMEA solution that is very user-friendly and easy to use. It comes with a step-by-step wizard that guides users in the creation of FMEA structures and displays entire FMEA structures hierarchically.

Users also have access to catalogs of products, processes, functions, failure modes, effects, existing causes, and control in an FMEA analysis.

SoftExpert FMEA also automatically calculates the risk priority number of identified failure modes and automatically sends preventive and corrective actions to users.

Users can visualize FMEA data using traditional worksheet format and create management reports highlighting failures in products or processes and the effectiveness of the preventive or corrective actions taken.

To cap it all, SoftExpert FMEA provides allows for multi-user system configuration allowing organizations to configure access rights to different users in an FMEA analysis.

Conclusion

An FMEA analysis is a proactive process that aims to find and solve problems even before they occur in products or processes and, in turn, enhance their quality. With software solutions that make conducting an FMEA analysis easier, it is important to utilize these tools and make FMEA analysis part of the development of a process or product right from the first stages and during its entire life cycle.

You may also explore some best GRC platforms for risk management.